Building restoration

- Surface preparation by using dry blasting or high pressure water jet – up to 2500 bar

- Cleaning with dust-free blasting technology – TORBO – reduction of dust by up to 95%

- Renovation of concrete constructions is carried out by using selected renovation materials

- Applied types of renovation materials used are in accordance with the European standard EN 1504

Cleaning work

Work with high pressure water machines 100-2500 bar (water jet)

We use several devices for cleaning and water jetting depending on the type of work and the power used. For general cleaning we use Kärcher and Falch machines. If higher pressures are needed, possibly with hot water heating, we use a powerful Falch unit (300 BAR), which is on its own undercarriage including a diesel engine and is completely independent of the water supply.

For pressures up to 2500 bar we use a high pressure pump WOMA MK– 3 and for pressures up to 1500 bar we use a high pressure pump WOMA 250 Z..

Use:

- renovation of concrete surfaces, bridges, stone and brick walls, cleaning of floors, cleaning of plaster and facades.

- cleaning of plaster, facades and roofing

- cleaning of runways and roads

- cleaning of service tanks, surfaces, sumps.

- cleaning of heat exchangers, pipelines, machines

- cleaning of sewage networks

Technology for perfect degreasing of DIRTY surfaces

Degreasing and cleaning work with detergents for filling machines FOC – 01 using high pressure water technology.

Use:

- cleaning and degreasing of floors and walls of production halls,- degreasing of machines – cleaning of tanks and pipelines etc.

Water jet cutting

High-pressure cutting unit: an illustrative example of water jet cutting of a concrete panel.

Benefits:

- Water jet cutting is without shock and thermal influence on the material to be cut, it is a so called cold cut – there is no internal stress on the material and its subsequent deformation.

- The machined part shows no mechanical, physical or chemical changes or deformations.

- Minimal beam force on the material to be cut, no micro-cracks are formed.

- Versatility – the beam cuts most materials over a wide range of cutting thicknesses.

- Water jet cutting is an environmentally friendly technology. No ecological unfriendly fumes are produced during cutting.

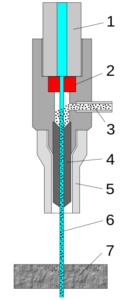

Graphical representation of the water jet cutting mechanism

1 – high pressure water inlet

2 – ruby or diamond nozzle

3 – abrasive

4 – mixing tube

5 – holder

6 – cutting water jet

7 – material

Materials that can be water jet cut:

- Reinforced concrete surfaces, stone, marble, granite, sandstone, tiles and others

- Structural steel, alloy steel, tool steel, aluminium, titanium, copper, nickel alloys and more.

- Plastics, rubbers, glass

Renovation of concrete structures

- HIGH-RISE AND ENGINEERING BUILDINGS – INDUSTRIAL BUILDINGS COLLECTORS

- TUNNELS – DRINKING WATER TANKS – SEWAGE AND SEWAGE NETWORKS

- CONCRETE RENOVATION – WORKING AND EXPANSION JOINTS

Restoration Technology:

Surface preparation by dry blasting or high-pressure water jet – 2500 bar.

Anti-corrosion protection of the reinforcement.

Reprofiling-renovation of the surface of concrete structures using selected renovation materials. Selected types of renovation materials such as Vandex, GEMITE, SIKA, etc. meet the conditions of the Ministry of Health of the Czech Republic for direct contact with drinking water.

Surface preparation with water jet 2500 bar. Removal of incoherent concrete layers, dirt and opening of concrete capillaries. This is followed by cutting the exposed reinforcement to 2/3 and cleaning it.

Anticorrosive protection of the reinforcement is applied to the prepared surface.

Subsequent rough reprofiling – levelling the surface to zero. This is followed by a full application of non-profiling material to increase the cover layers of reinforcement. Final layer – in this case for waterworks surfaces.

References

Repair OK of the lock bridge, Beřkovice

Years 2014 – 2015

ČEZ POČERADY

Renovation of piping systems

Litoměřice hydropower plant, Kopisty

PVE Dlouhé Stráně